Intellectual Property (IP) Ownership in China

There is something very important I wanted to talk about Product Development in China and this is related to IP ownership: this is the differences of business model between east and west when considering product development.

Indeed, there are many people who have misunderstanding of how the IP business model is structureed in China, and quite often they get surprised when they discover they can not access some parts of the products they have developped with their chinese manufacturers to move their production somewhere else after they got disappointd by the first one (for quality or price reason). So, I am going to clarify this point a bit.

Western business model for electronic product development

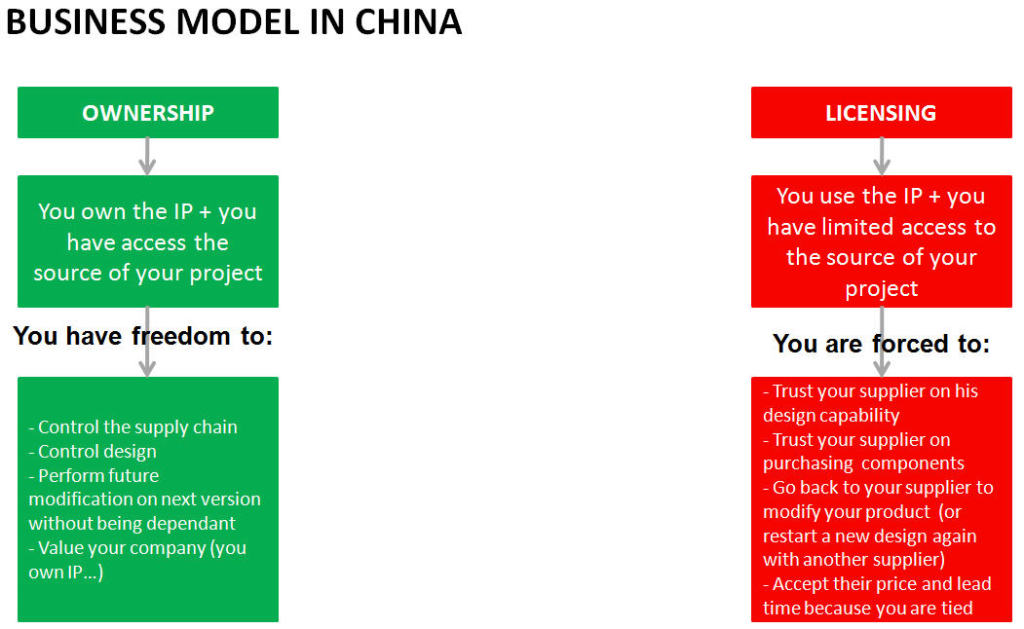

If you perform an electronic product development in the west you are probably going to hire a product development agency or an electronic engineering company to achieve your design and your engineering. You are then going to pay a significant price for their engineering service (may be something between 10 000 USD to 30 000 USD) but in the end they will deliver all the sources of your project and will sell the IP they have generated to you.

On this base, you will be the owner of the IP because you purchased it, and will have in hand all the keys of the puzzle necessary to manufacture your product wherever you want.

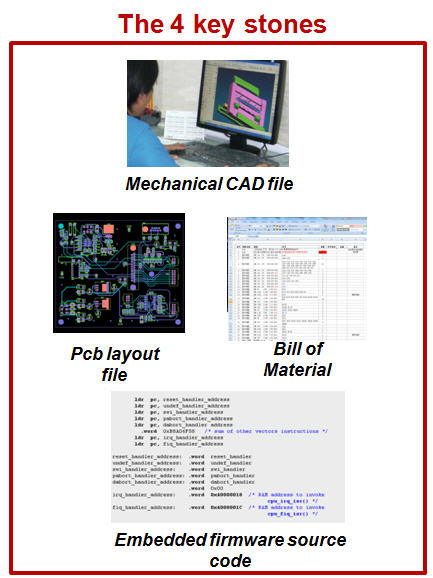

In the electronics field this IP is normally structured around 4 main keystones : Mechanical Engineering CAD file for mechanical part (enclosure, joint part), PCB layout Design, Bill Of Material (BOM), and most importantly Firmware also called Embedded Firmware (usually being a C program source code being compiled to be runned on a chipset).

If you have access to all those 4 key stones you are free to perform your electronic manufacturing anywhere you like, you are free to perform electronic design service for change whenever you want, you have full control on what your product is made from (electronic supply chain), and you can value your company with IP ownership (which can be usefull to get some investors sometimes)

Far east business model for electronic product development

On the other end, if you develop in the far east you may be in another configuration. Most of time the supplier (manufacturer) will propose you some small cost to perform some Electronic Engineering Service, Industrial Design Service or adaptation of their existing product, in exchange you will have no other choice than manufacture your product with this same manufacturer (as contrary to western engineering, the asian supplier will not deliver to you the 4 keystones so you are tied with them for manufacturing). For those small fees, they will not grant you IP ownership (they remain the IP owner), and then you are in the scheme of a kind of licensing.

A licensing means you can use but you don’t own. It also means that potentially those IP and sources are shared with others clients as it belong to manufacturer, he is free to use them for other potential customers. It cost less to develop but you also get less.

What dos it means in the end ?

- It especially means that you are tied with supplier for production whatever it happens.

- It means you are forced to work with them for production and for future modification of your product.

- It then means you are directly dependent on them for your supply, potential debugging, and other technical support.

- It also means that if they disappear or go to bankruptcy (as it may happen in China) then you have nothing, and you will need to restart your project with another supplier from scratch, potentially interrupting your supply chain distribution. But this is not the worse.

- The worse is that having limited access to the source of your project, you also have limited control on it: this particularly include control on supply chain and traceability of components = quality control of the electronic. And guess what? This is when you loose control on the supply chain and its traceability that you start having trouble on quality because then quite often the manufacurer may start cutting corner on components and raw materials.

I recently got a customer who told me they had problem with their electronic product (here it was tablet) because the manufacturer company they were buying from had used second hand and fake flash memory in their product instead of using brand new genuine one. They asked me how they could have avoid this. I asked them if they had access to the Bill of Material and if they had access the supply chain to trace where the components where coming from. They told me no…. This would not have happened if the bill of material and the sub-supplier chain had been under control.

So be very careful of which strategy you should adopt and what you are ready to sacrifice. Sometimes it is better to pay a bit more but to be free of your move especially if your product is supposed to be unique and your asset to attract market.

I see almost everyday some customer willing to develop electronic product in China but who lack the access to the 4 keystones, making that we have to make again their whole engineering to be able to produce for them.

Below is a graphic which resume well the situation.

I hope this has been usefull to you to understand how the business model work in China contrary to the western business model, and why you should weight pro and con about which which Product Development strategy should be adopted.

Leave a Reply