When buying goods in China while considering quality inspection and quality control processes to make sure the quality of goods before shipping them overseas, there are generally two ways to perform those quality check operations.

One of the most common dilemna an importer or an international buyer may face is to choose to perform a quality inspection with a sampling methodology versus performing a 100% quality inspection (also called Total Quality Inspection or Full Quality Inspection).

In this post, I briefly explain what are the differences, similarities and what are the advantages and drawbacks of each technics.

# Quality Inspection in China with a 100% Quality Inspection

The 100% full inspection, as its name apply will inspect the whole lot of products ordered by the buyer to the supplier. Normally, your vendor should have done a 100% inspection of its mass production before packing the goods himself. All factories should inspect all manufactured goods before packing them into carton.

Why the hell should you then do a 100% inspection after your vendor is supposed to have done it already ? Well, believe me or not but sometimes the 100% inspection made by vendors is just inefficient and still some defective are passing through the filter. Sometimes it is 0.5% , sometimes 1%, but sometimes it can also be 10 or 15% (more dramatic).

If your product lot size is high and if the required time to inspect each unit is long, then your 100% quality inspection will take a lot of time. And if you contract with a third party inspection company to perform this inspection, then several man-day of works might be necessary to complete the 100% quality inspeciton of your goods.

I am sure you understand that if your product value is 1 to 2 USD per unit (let’s say a promotional or a gift product) and that quantities ordered are in high volume then a 100% quality inspection might not be a good solution because the cost per unit of the quality control operation might weight a substantial part of the product cost once shipped.

However if you are buying some products with high added value such as luxury goods, first you probably want to make sure your product is just perfect, second the cost per unit for performing qc on each piece might be neglectable face to the product cost. Hence, you would inspect 100% of the goods again after your manufacturer did so, just to make sure you will not get any problem.

So, in short what are advantages and drawbacks of quality inspection with 100% inspection ?

Advantages: When using a 100% inspection, you don’t rely on statistic and you completely eliminate the randomness factor which may bring biased result to your quality control.

Drawbacks: If your lot is large, then you may need several man-days to inspect your goods properly.

# Quality Inspection in China via a Sampling Methodology

If you have no notion of what quality inspection sampling is, you can just think about it in terms of statistical or probabilistic analysis applied to quality management.

In order to explainin a simple way what is a sampling quality control is, I will use a very simple analogy:

When an election for presidency is approaching in a country, surveys are made to evaluate what the outcome of the election is going to be. Quite often we usually know a few days before the official result what the percentage for each candidate will roughly be. Journalists are not able to predict the future but still they success to get very near to the real result, this even several days before the final result. So how do they do ?

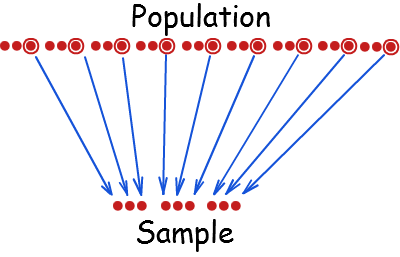

Well, most of time, they mandate a market survey company. A sample of N persons will be drawn randomly in the population and will be asked to answer question to know what they would vote at the election day. Drawing those N person among Y people total (the whole population of a country) is called a sampling. Of course, the more people are drawn (the higher N is), the more chance to get an accurate estimation.

In quality management, and particularly in quality control, we use the same technic to evaluate the quality of product lot. When we perform inspection via sampling: we draw N products among a whole lot of Y products. Then, we inspect the quality of those N products and we estimate that those N products represent the whole lot of product Y. Hence, if among N products drawn, we find out 10% of defectives products, then we consider the whole lot containing Y products will approximately reflect 10% defectives.

This is a probabilistic approach to get an estimation of the reality. As it rely on probabilistic and statistical approach, there is always a possibility of error due to random factor. For example, if the inspector is unlucky and draw only goods products in cartons, then the inspection will reflect a lot with no defectives at all whereas some could have been found on the next cartons…

Now, imagine that you are inspecting screws for dimensioning of their length. Imagine how many screws can be stored in a full 20 feets container. Probably a millions. The value of a basic screw is usually extremly low. Are you going to inspect 100% of a 20 feet container of screx to verify the dimension of them? Probably not because the unit cost allocate to measure dimension correlated to the salary of the inspector might overweight the cost of the screw itself. So, in this case you would probably use a sampling methodology rather than a 100% quality inspection

So, in short, what are advantages and drawbacks of quality inspection via sampling ?

Advantages: The main advantages of sampling is that if your product lot is too large to inspect 100% of the product (mostly due to time and budget reason) then you have a statistic based methodology to assess the quality of the whole lot without really doing it. As most of time quality inspection is billed on man-day unit, the more products to inspect the more man-day needed, hence the more man-day to bill to the client.

Drawbacks: As only X products over Y are inspected, then there is still a part of risks of getting a biased or unreliable assessment of the quality of Y. Indeed, if by mistake the inspector draw products which are good whereas others in the lot are not, then the result of the assessment is not representing enough well the reality.

This may happen in some certain situations where the inspector would draw sample in a not enough randomly well manner: for example, if cartons are stored and piled up in a warehouse in a way that some cartons are difficult to access on the back of the pile, then the inspector may not pick those cartons (normally he should pick cartons in a total random manner in the whole pile of cartons in warehouse).

# A trick

Normally to avoid getting wrong data on quality inspection via sampling methodology, the best is to spread at the maximum the drawing of the samples into many different cartons spreaded in different area of the warehouse. By increasing the picking into cartons which are not located near to each other you also increase the chance to have a more representative situation of the reality.

So, if you contract with a third party inspection company in China or in Asia to perform your quality control, make sure they pick cartons randomly and in the most spreaded manner.

I remember that in the past when I was inspecting goods myself, vendors were not very happy when I was asking them to pick cartons being located and hidden behind the pile in the warehouse. They had to move all the cartons on the front first, then pick the cartons on the back, then put back all the cartons again. It made them make a lot of effort just to pick a carton on the back which they claimed was the same than the one on the front. Yet, I knew that sometimes some vendors are smart and hide cartons with defective products on the back of the pile in the hope that the inspector will not select them and will not see defectives.

Make sure the quality inspection company you appoint to check your goods will do its job properly and entirely !

# Conclusion

You should choose the quality inspection methodology based on your own situation:

If your products are high end one and you can not afford a product not being perfect because your customers are highly demanding, and if you have enough budget and time, then you should opt for the 100% quality inspection methodology.

On the other side, if your budget is a bit tight, your volume are high, your product value are low, or if you are ready to accept to rely on a random and probabilistic based methodology (hence accepting unluck too in case of bad luck) then you should probably use a quality inspection methodology based on sampling.

Leave a Reply