Why supply chain management consistency is important

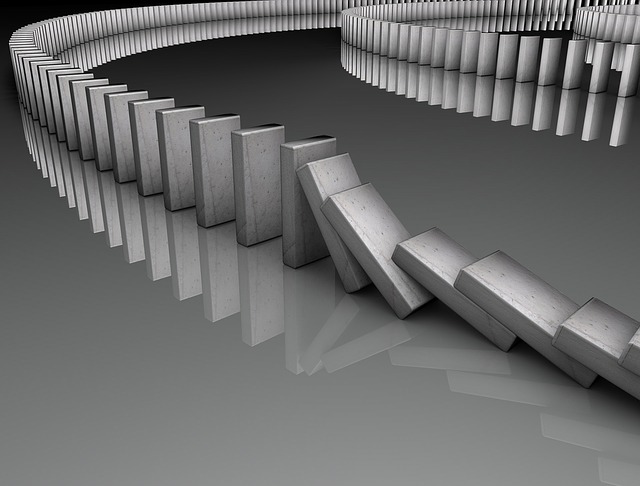

If you are a serious retailer or distributor, you know that supply chain consistency is important because a hole in the supply chain may cause you to be out of stock. Being out of stock not only mean that you loose money not being making a sales, but it also means you look unreliable in your supply to your customers.

Having a flaw in the supply chain can come from different reason: short supply of an upstream element in your manufacturer supply chain, logistics issue, quality issue making delay in supplying.

How supply chain and quality management are tied together.

One of the common issue importer may face with their suppliers is the consistency of the supply chain.

By consistency I mean “always getting the same level of quality and quantity available for an ordered product”, in short “making sure that every time you need to fill your warehouse with a reference you can make sure you will get it on time and with an acceptable level of quality in orde you can sell it without having any complain”.

I have seen in the past many importers facing issue with this matter.

Problem was going from “my supplier can not deliver before 6 months” to “quality is fluctuating from order to order”.

What are the causes of unconsistent supply chain

I was quite often contacted by those importers who were requesting my help to solve their issues.

80 to 90 % of the time those people had wrongly selected their supplier (please note I say “supplier” not “manufacturer”) and didn’t control the supply chain. I have seen mostly two cases :

1./ Lack of transparency

Quite often they were buying from trading companies who were changing the manufacturer order after order in result the delivered product was never exactly the same. This typically happen when a trading company will select a good but expensive supplier at the beginning to comfort the importer to increase its quantities and then later switch the good supplier by a cheaper one but also worse one. Suddenly the importer start receiving product with worse quality and doesn’t understand why.

2./ Lack of control on manufacturing process

Sometime they contract with “manufacturers” who don’t manufacture or don’t manufacture fully the products for every orders by themselves.

When quantity are high and manufacturer doesn’t have enough production capacity, in order to reach the deadline they will sub-contract a part of the production. As manufacturers are different their sub-suppliers (raw materials for example) are also usually different and the manufacturing process are also different. Rarely both manufacturer sync themselves to get an uniformed production. In result the production become inconsistent and quality is fluctuating.

Those two cases briefly explain how quality can become inconsistent even after several orders placed to suppliers. Who fault is it ? The fault is for great part to the importer who didn’t select his supplier enough well during sourcing phase. Too many of them get attracted by free sourcing of trading company and by attractive low price which in turn impact product quality.

And you, what is your experience about it ? Have you already experienced this kind of issue ?

Leave a Reply