From my experience, here are a few characteristics of a good plastic injection company in China:

1./ The general manager / owner has a technical background (not a sales one )

For me this is a very important point. If the top management doesn’t understand the technical part of his company then even he has other people who knows it will never make the company very reliable.

2./ The plastic injection company has business and management process in place to perform the following control:

a./ Procurement of material (to avoid swap of materials)

b./ Production process (to achieve repeatability on production)

c./ Quality management system in place at different step of the production (at the entry of the material into incoming warehouse, during production, at the end of the production)

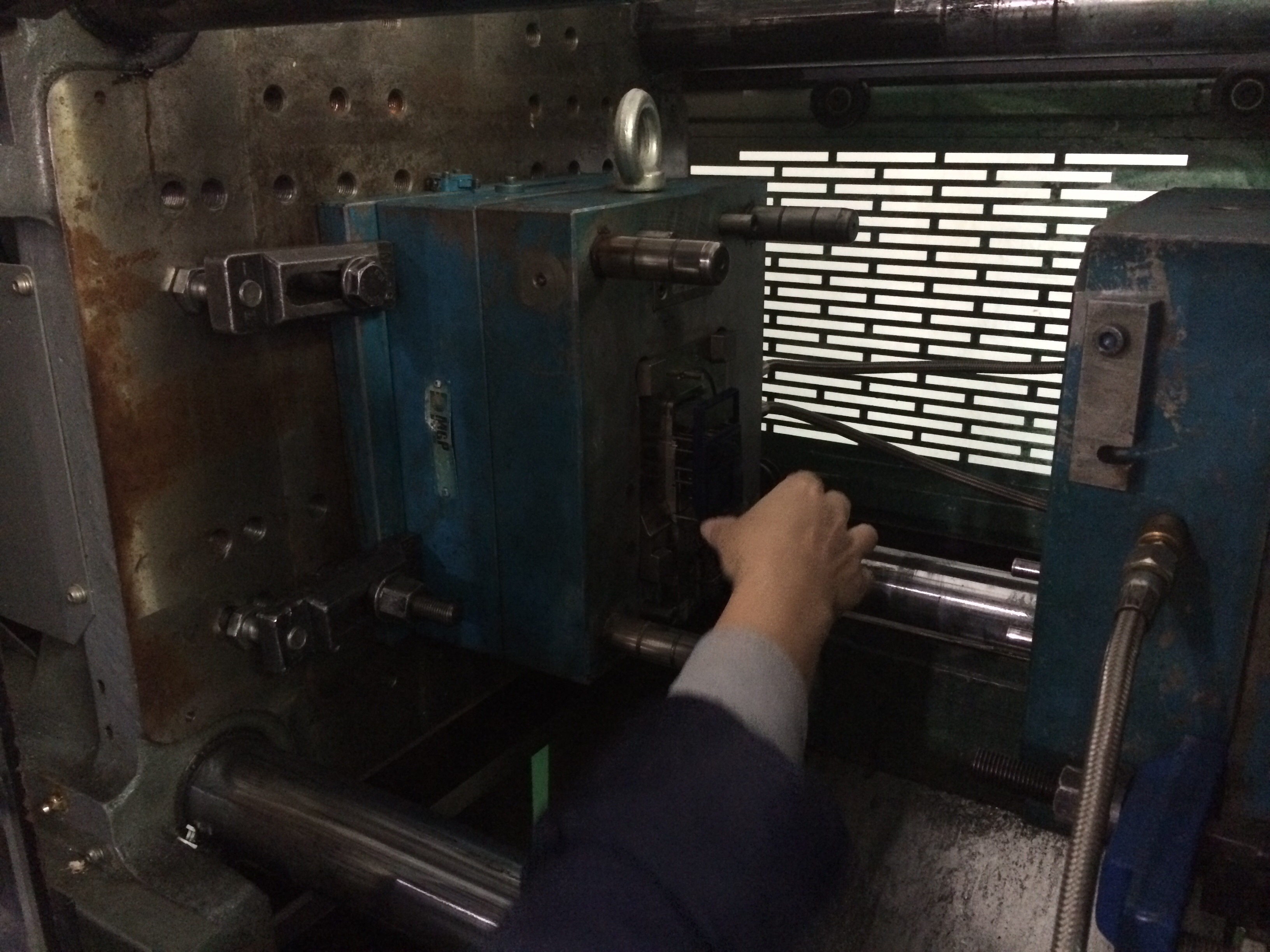

3./ Machine maintenance is performed properly at the right time (this include calibration, cleaning etc…)

If machines are not calibrated properly and regularly then the change to get some slippage on quality is high over the time without they don’t understand why themselves.

4./ Plastic injection company has training process in place

As turnover in China is rather high, they have to be able to replace any worker at any time while the production and the quality of the production being impacted by the change of worker. Very few companies have this in place in a effective way.

5./ Plastic injection company has production and quality record in place

How many defects are produced on each production, what kind of defects, what are the cause, on which shifts are they product etc… This allow to have a traceability and good control of what is going wrong, when and how

6./ Company has plastic tooling manufacturing in-house.

It is much easier and remove a lot of headache to have everything in house because it allow avoiding incompatibility between stake holder such as “the tooling doesn’t fit the machine” It also avoid to loose control on the IP as most of time you will need to transmit your CAD file as source file to create your parts.

7./Their employees and particularly their engineer and production manager are qualified.

The sales should be too. Don’t rely on what you hear, rely on what you see they do and what they really know.

The easy test is to ask a lot of technical questions to those guys and to assess their knowledge. If they tell you : “we always do like this, and we don’t know why” then you should look elsewhere.

I personally like manufacturers who know what they are doing and who are able to master their core business because the day when you have a problem they can identify and fix problems quickly. If they have to rely on X or Y to try to understand the problem then it can take ages to solve it.

I regularly challenge manufacturers I visit with the WHY methodology to see how they react (particularly with the people you are going to be in touch with).

The typical stereotype is the young Chinese sales who has an english degree as background who is able to speak english, push a quote to you but when you ask some technical details she will tell you “wait! I need to ask the engineer”, this mean those people don’t take the time to understand what they are doing, what they are selling and for me they are the worst sales ever…

I used to work in the past with this kind of people for MP4 player, I ended producing the product on our own assembly line as I was so tired to know more technically that the people from factory.

8./ The environment is clean and ideally dry.

In south of China the humidity rate is very high. Quite often when you inject plastic you need to dry it and deshumididy it before injection so that if there is temperature variation over time your part will not crack. Some manufacturer don’t dry anything and just put the plastic material in their machine and inject straight away. Worst if their press have no hoper dryer it means they inject without drying at all. It simply means they don’t know anything what they are doing and they believe plastic injection is just melting some plastic by placing some granule into a machine and by pressing buttons

9./ Tooling should be maintained

Tooling should be properly stored on shelves and ideally packed to isolate them from atmosphère. Ideally, the transportation between the shelves and the machines should be down with a crane and not by hand. I have seen some plastic injection companies saving money on crane and moving tooling out of the shelves by hand. There is a risk of letting the tooling fall down on the floor

10./ Capability to segregate bad plastic part.

Like always, the manufacturing game is to avoid passing defects out. A typical question I ask is “How much % of part do you scrap ?”. I know by experience that some parts can be very difficult to produce, so most of time I would pick in their showroom a part I estimate difficult to manufacture and I would ask the question to see what they reply.

If they reply ” a very low percentage about less than 1%”, I would know they are probably liying or they don’t know really the number = thy don’t have record = they have no control on what they do. I prefer an honest supplier who would tell me: “around 12.3%” because then I know this is more realistic and because I know they really know what they are doing.

11./ The company doesn’t necessarily need to be big.

I have seen some plastic injection companies having 2–3 press only but doing a very good job because they master what they do.

PS: I sometimes help oversees companies to update their plastic injection supplier by supplying some consulting. I also have access a set of sub-contractors which I have already taught and help to update their capabilities. If you need plastic injection, feel free to contact, I will be happy to help you to manufacture your parts as we have also service of plastic injection in our company.

Leave a Reply