The confusion between engineering and prototyping

I receive quite often the following request from customer willing to develop new product in China :”I want to make a prototype, can you please quote me?”. And when I ask :” do you have the source file of your project?”, quite often the answer is “no, we don’t”. So apparently, many people are confused about what is prototyping activity and what is engineering activity.

I wanted to writte a blog post about what is the difference between making a prototype and realizing engineering for a new product because many (but not all) people seems confused about the differences and relationship between both. So, I will clarify how engineering and prototyping are two activities which are more less interrelated to each other but which are actually totally different, and this especially when prototyping and engineering are made in China.

How Engineering is usefull when performing product development

According to Wikipedia ” Engineering is the application of scientific, economic, social, and practical knowledge in order to invent, design, build, maintain, research, and improve structures, machines, devices, systems, materials and processes.”

In my personnal point of view, engineering is the process of transforming an idea or a concept into a makable product by processing with a logical structure of development and design work to achieve the product respecting customer requirement. The engineering is a substantial part of the added value creating the product from just an idea. It based its activity on using relevant technics to achieve the requirement of the customer or principal by using scientific structured and organized approach.

Engineering may indeed involves a very broad range of activities and in the case of developing a new product with engineers, the involvement of several field of engineering might be required: mechanical engineering, electronic engineering, thermal engineering, and many more for special industry (think about aerodynamic for aircraft or drone product development for example).

Most of times, those engineering are interrelated. For example, when we perform mechanical engineering in China for developping an electronic product, our mechanical engineers have to coordinate with our electronic hardware engineers to make sure mechanical parts and PCB can fit together

What is prototyping

When we are involved in new product development, the prototyping activity is the fact to take the engineering data and to transform them into a real product which is fabricated at low production scale (normally between 1 to 20 pieces).

It can be mechanical part prototyping or electronic part prototyping and it is made in small series only. (See our other blog post: “Make electronic prototype” and “Make part prototype“). Prototyping is the consequence and result of the engineering.

How engineering and prototyping are related to each other during product development

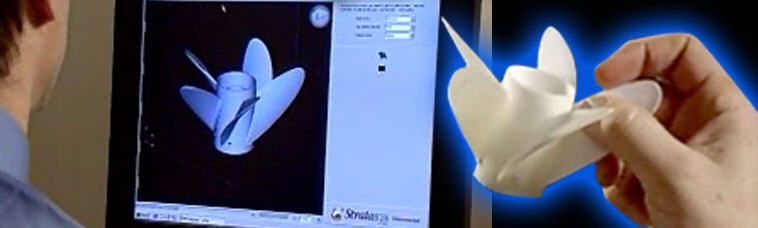

As indicated earlier, the rapid prototyping activity is one of the result of the engineering because it comes after the engineering is over. Without engineering activity being over, prototyping is almost impossible. The prototyping comes after the engineering being done because to make rapid prototyping such as for pcb board protyping (which require drilling, cutting and routing made in an automatic way) or plastic part prototyping (requiring CNC maching, SLA or SLS process) with machine, those machines have to be fed with file design (Gerber file for PCB, CAD file for CNC or SLA/SLS) which are made during electronic engineering and mechanical engineering. So the prototyping stage is directly dependant on the engineering phase.

Using prototype to validate partly engineering

The prototyping activity is one of the methodology used for validating the engineering previously done. Indeed, engineering are today mostly done by computer and it may be sometime difficult to “feel” a product without having a minimum of physical item in hand. A lot of simulation can be done by computer but nothing will ever replaced to have a real product in hand to test and verify that it match what you want.

Using prototype to convince investors

Yet, most of start up we work with use a prototype to convince investor to fund them. Our clients use prototype as proof of concept to demonstrate the credibility of their idea and that their product can work.

Using prototype to establish a reference for mass production

Prototyping is also used to generate reference sample before entering into tooling fabrication in China and manufacturing. Indeed, if you manufacture a new product in China, then you have 99% chance the supplier to ask you “do you have a sample you can send to us?”. This simply means in other words “do you have a reference that we can copy or reproduce”. It may sounds weird because when you are in product development stage you may not have already a product in hand…unless you have prototype 🙂

I actually understand very well this because it is much easier and much faster to develop a tooling having a physical sample in hand as reference than using only Computer Assisted Drawing file (although having a CAD file would be better). Normally, an experienced chinese tool maker shoudl be able to use only the CAD, but it is always better to supply them a physical sample for comparison to avoid any possibility of misunderstanding.

Not only, it is faster and easier, but it is also an help to avoid mistake, error (for dimensionning for example) and to have a comparison tool. It can be used as a reference sample for quality control purpose.

Use a prototype to estimate cost of manufacturing and assembly

A last use possible of prototype is to estimate the cost for assembly. Quite often our customers ask us to estimated the cost of mass production for a product that doesn’t even exist yet. In this case there are two possibilities: either we propose them some Feasibility Studies and Cost Estimation, or we ask them to supply us a prototype so we can simulate the assembly to estimate the cost of the assembly.

Because to estimate this cost you will normally need to assembly the product by yourself from scratch at least one or two time and calculate a bunch of parameters that can influence the assembly cost. So having a prototype in hand is a real help.

In a conculsion we can say that prototyping can be considered as a verification or validation step of the engineering activity and can be usefull for many other reasons.

What is your opinion about it ? Have you already made prototype on your own how is your experience about it ? Feel free to share your opinion

Leave a Reply