I sometime get amazed by the behavior of some production or quality managers when a quality issue rise on production in China. Quite often, they will try to supply with a solution on the current batch by patching the problem with a short term correction without fully understanding why and how this quality issue happened. Yet, correction doesn’t provide a long lasting solution. Normally they should investigate the root cause in order to provide a corrective action plan so that the considered quality issue never happen again in the future. This provide a proactive solution and not just a reactive one.

A typical example: if an electrical appliance product break out and doesn’t work anymore due to fuse melting after a surge of current, then the factory will just replace the fuse but will rarely investigate why a surge of current happened in the system to prevent it to happen again.

Why chinese manufacturers don’t always perform root cause analysis

Well, you have to understand that root cause analysis is time consumming and require technical or engineering skills. For example, in the case of an electrical appliance it means that the engineer in charge of design of the product should normally review the design and defective unit to analyze the reason why the product broke out.

Problem may comes from design, conception, manufacturing, equipment, workmanship, procurement, environment, processeses. In any case, investigation to search in the right direction can be laborious, complex and for sure time consumming.

Quite often, with necessity to ship their goods quickly to their overseas customers, some manufacturers consider they just don’t have not enough time to manage problem. Hence, they deal with them on the spot on a short term minded way instead of investing a bit more time to find a long term reliable solution which would avoid them wasting time later again on the next batch.

Another obstacles to performing root cause analysis for improving a process is simply just potentially a lack of process itself, training or documentation in the quality management system of the manufacturer. Indeed, the fact to establish a correction action plan after a root cause analysis being done is not naturally automatic for everybody.

If your quality management system doesn’t tell you to do it or if you have not even been trained to understand the importance of doing it, then you might just skip it. So, I would say that root cause analysis and corrective action plan establishment will not be an obstacles if and only if the considered organization have effectively implemented a root cause analysis and corrective action plan procedure in its quality management system.

Using Fishbone diagram for root cause analysis

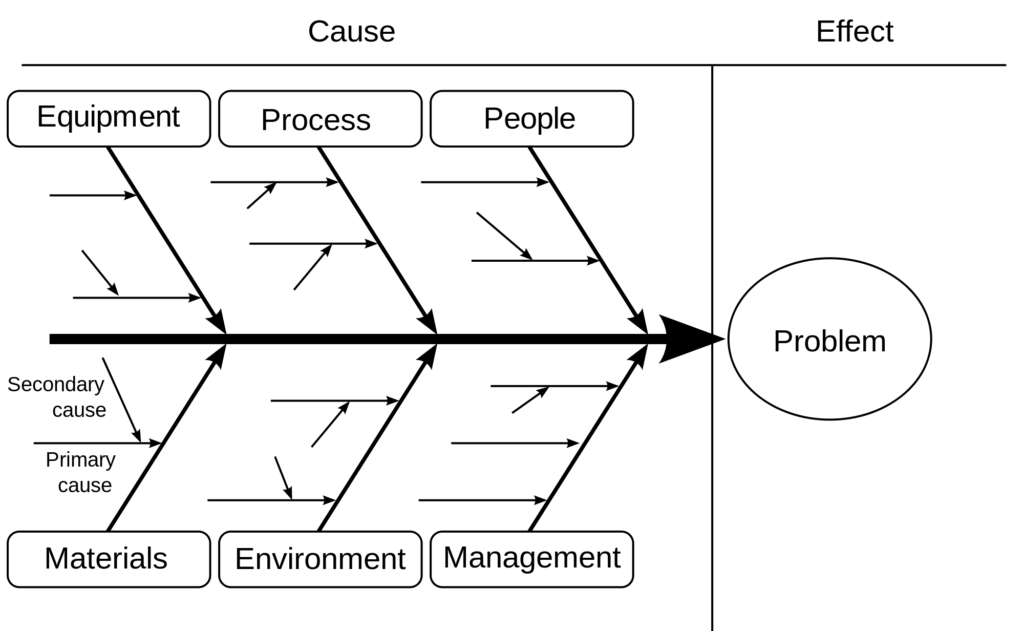

When trying to identify root causes related to quality issue on manufacturing environment, different methodologies can be considered. One of the most used root cause analysis methodology is called Fishbone Diagram, Cause and Consequences Diagram, or in the Lean Manufaturing verbiage “Ishikawa diagram” (name from its creator, which of course was Japanese 🙂 ).

Lean and Six Sigma practicionners use this diagram to help mapping potential causes generating issues in their systems.

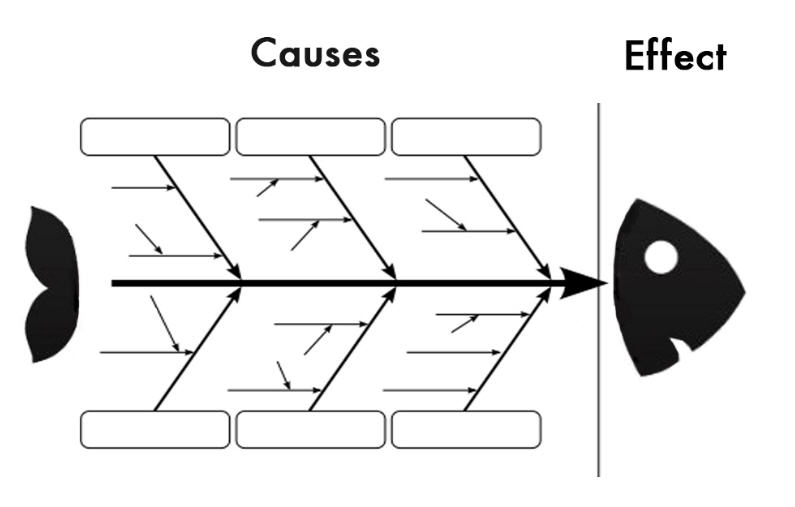

A typical fishbone diagram looks like the one below (and you will understand quickly why it is called fishbone diagram: the diagram really looks like a fishbone). Most of the technics consist in categorizing the potential causes and to use the “5 whys” methodology where you ask 5 times why something happened by deepening the question.

Fishbone diagram is typically used for structuring a brainstorming session. It list and identifies many possible causes for an effect or problem. It allows to immediately sorts ideas into useful and different categories.

How to use a fishbone diagram in a real case

Take a big sheet of paper or use a whiteboard

1./ Define the problem and agree on the effect of it => fill the head of the fish with it

2./ Attempt to identify the possibile categories which may generated this problem. Typical one in manufactured product environement would be:

- Methods and processes

- Machines (equipment)

- People (manpower)

- Materials

- Measurement

- Environment

- Design / Conception

Use those categories to create the bones of the fishbones

3./ Brainstorm and attempt to identify all the possible causes of the problem. Ask to youself and to everybody: “Why this is happening?” . For each idea given, write it in a sub-branch in the bones categories which you think it belongs. Causes can be written in several places if they relate to several categories.

4./ Keep asking “why does this is happening?” for each cause. Add sub–causes branch off the causes previously written. Keep asking “Why?” and keep generating deeper levels of causes.

5./ Once the group of stakeholder taking part to the root cause analysis runs out of ideas, focus attention to area on the chart where ideas are few

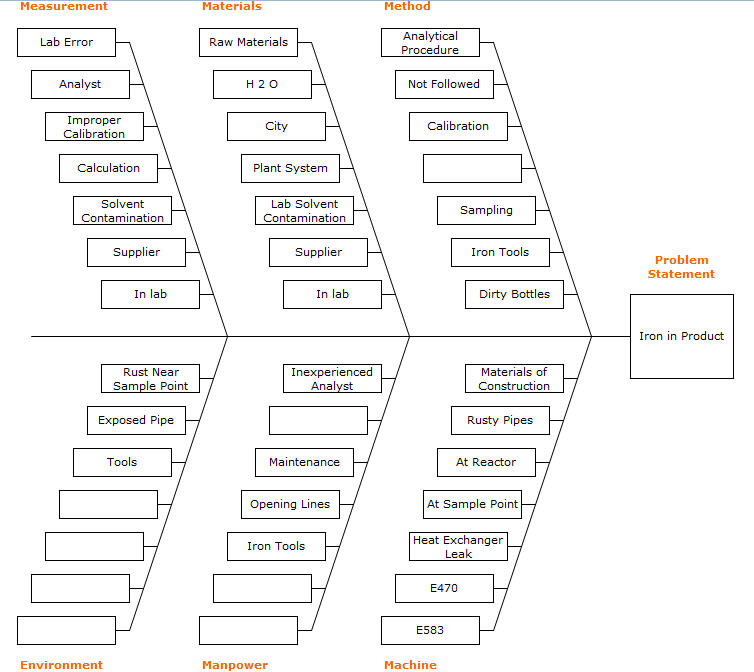

Here is the result below of whatcan give a fishbone diagram for quality manufacturing issue related to the prsence of some iron particules into a metal part which should not get it:

Advantages of fishbone diagram

The main advantages of fishbone diagram is it is extremly visual and it helps to pave the way to the root cause research in a graphic environment much more user friendly than words on a paper.

If you have any quality issue in your manufacturing or production, I invite you to use this methodology which is quite efficient.

What is your experience ? Have you already used this kind of tools ?

Leave a Reply